Teyler Eliminates Excel Once-And-For-All with No-Code

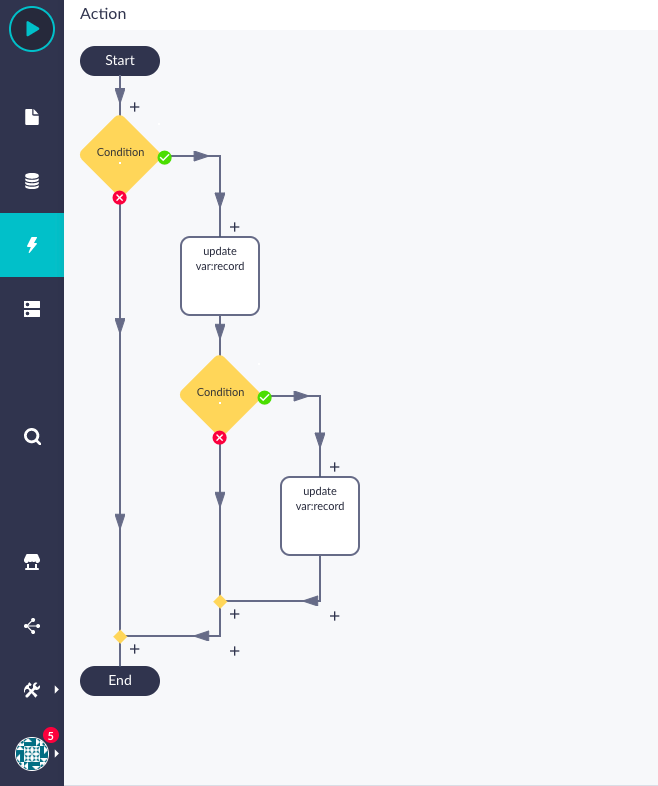

Process and project control system

All information revolving around projects from materials and contractors to equipment is stored in real-time for consultants or clients to log in and monitor.

Report automation

Lex's application uses built-in logic from industry experts to generate reports for Risk Management and predictive analytics.

Customer portal

Clients are able to log in to the reporting or database system where they can download up to date versions of their project analytics.

© Copyright 2025. All rights reserved.